Reactor 3 E-XP2

Overview

The Reactor 3 E-XP2 is a polyurea system built for customers looking for a machine with more output and capabilities. It is ideal for use on medium to large jobs and applications. The E-XP2 is an ideal machine that can be the workhorse of your fleet, capable of handling most types of jobs with a good mix of output, heat and features.

Details

The Reactor 3 E-XP2 is a polyurea system built for customers looking for a machine with more output and capabilities. It is ideal for use on medium to large jobs and applications. The E-XP2 is an ideal machine that can be the workhorse of your fleet, capable of handling most types of jobs with a good mix of output, heat and features.

Upgrade your rig with a powerful Reactor 3 proportioner, built with advanced capabilities for spray foam applications. Reactor 3 is designed to communicate with the entire system to simplify the operator's job, optimize spray parameters and maximize productivity.

Reactor 3 Electric Proportioner

Designed to run quietly and efficiently, the Reactor 3 Electric Proportioner communicates with the entire system to simplify operations, improve performance and reduce maintenance.

Reactor Connect

Control your system with Reactor Connect and be more productive. Access your Reactor right from the gun. Monitor and adjust your proportioner and keep right on spraying. No hassles. That means you can get more done in your day, with less downtime and better yield.

Xcelerator Heated Hose

Internally or externally heated hoses are independently temperature controlled. The internally heated hoses have 40% faster warm-up times and are 10% lighter than the traditional externally heated hose. Internally heated hoses are now available in 50 ft and 100 ft lengths to minimize weight and fluid connections.

Core E1 Transfer Pumps

Designed to optimize material supplied and minimize downtime. Quieter than your typical pneumatic pumps, while also able to communicate with the Reactor 3 to create a fully-connected system.

Features

- Katalyst: Reactor Intelligence from drum-to-gun. System communication and control that improves performance, ratio and yield

- Auto Pressure Balance: Reactor automatically adjusts temperatures to optimize fluid pressures and maximize yield

- Supply Pump Shutdown: Automatically shuts down when you run out of material. Prevents air from entering the system that can cause off-ratio issues. (Requires Core E1 pumps)

- Smart Supply: Automatically monitors and adjusts fluid inlet pressures to compensate for high viscosity (e.g., cold) materials to keep you spraying on ratio (Requires Elite Reactor paired with Core E1 pumps)

- Resistance Control Mode: Accurately monitors and controls hose temperatures without the hassles of fluid sensors and RTD cables

- Power Management: Select desired heater wattage for reduced power consumption

- Cellular Software Updates: Automatically stay up to date with the latest Reactor software (Requires Reactor Connect)

- Jog Countdown Timer: Input a cycle count value and have the machine run and shut off after that exact value to assist if precisely flushing the system

- ISO Lube Pump: Active ISO Lube system with peristaltic pump features automatic timed circulation to improve TSL Life. Reduced maintenance (No check valves). Larger easy-to-change ISO lube bottle

- Reduced Size: Compact design protects the flow meters and hose connections from being damaged in your rig

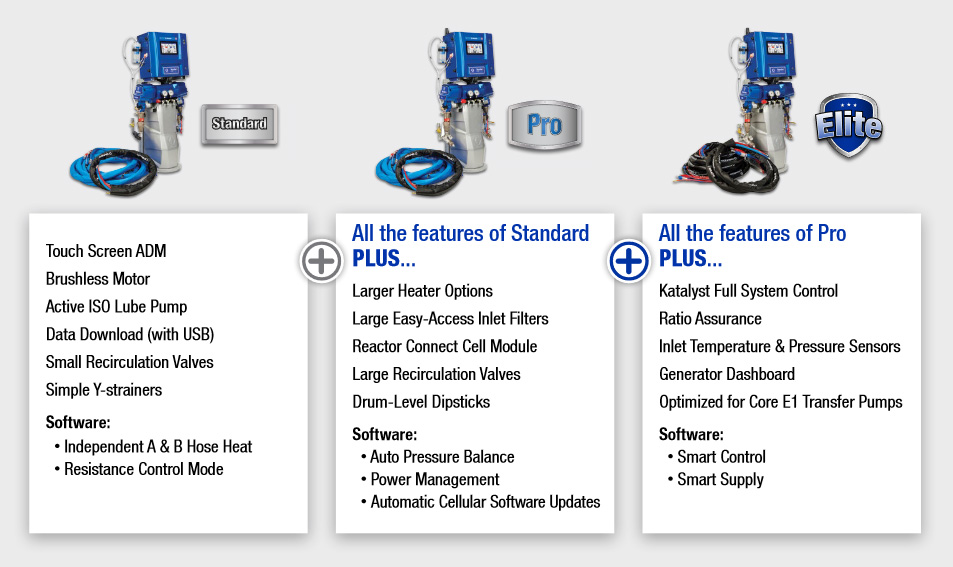

* Some features and software are only available on Pro and/or Elite models

|

Standard |

Pro |

Elite |

| FEATURES | |||

| Touchscreen ADM | ✓ | ✓ | ✓ |

| Brushless Motor | ✓ | ✓ | ✓ |

| Active ISO Lube Pump | ✓ | ✓ | ✓ |

| Data Download with USB | ✓ | ✓ | ✓ |

| Simple Inlet Filters (Y-strainers) | ✓ | ||

| Large Easy-Access Inlet Filters | ✓ | ✓ | |

| Small Recirculation Valves | ✓ | ||

| Large Recirculation Valves | ✓ | ✓ | |

| Large Heater Options | ✓ | ✓ | |

| Reactor Connect Cell Module | ✓ | ✓ | |

| Drum-Level Dipsticks | ✓ | ✓ | |

| Katalyst Full System Control | ✓ | ||

| Ratio Assurance | ✓ | ||

| Inlet Temperature & Pressure Sensors | ✓ | ||

| Generator Dashboard | ✓ | ||

| Optimized for Core E1 Transfer Pumps | ✓ | ||

| SOFTWARE | |||

| Independent A & B Hose Heat | ✓ | ✓ | ✓ |

| Resistence Control Mode | ✓ | ✓ | ✓ |

| Auto Pressure Balance | ✓ | ✓ | |

| Power Management | ✓ | ✓ | |

| Automatic Software Updates via Cellular | ✓ | ✓ | |

| Smart Control | ✓ | ||

| Smart Supply | ✓ | ||

| INCLUDES | |||

| Externally Heated (EH) Hose Packages Available | Yes | Yes | Yes |

| Internally Heated (IH) Hose Packages Available | Yes | Yes | Yes |

| Whip Hose Length | 10 ft in EH packages, 20 ft in IH packages |

10 ft in EH packages, 20 ft in IH packages |

20 ft in EH or IH packages |

| Single Heated Hose Package | 1 x 50 ft EH or IH packages | 1 x 50 ft EH or IH packages | 1 x 50 ft EH or IH packages |

| Multi Heated Hose Package | 4 x 50 ft EH package, 2 x 100 ft IH package | 4 x 50 ft EH package, 2 x 100 ft IH package | 4 x 50 ft EH package, 2 x 100 ft IH package |

| Engine Cable | No | No | Yes |

| Packages with Core E1 Pumps Available | No | No | Yes |